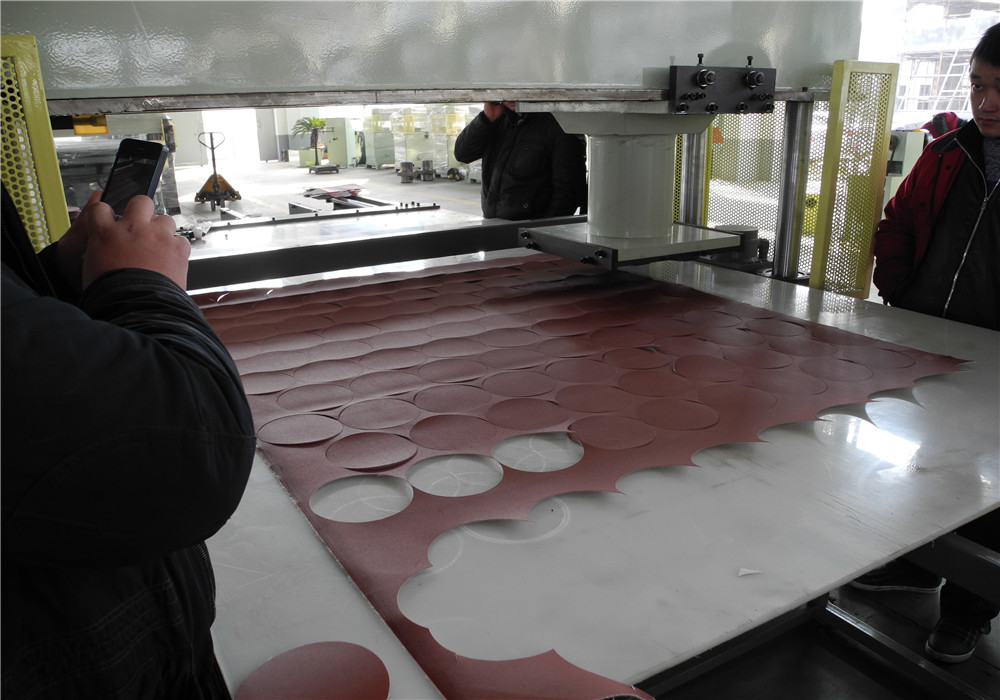

Automatic Traveling Head Beam Press For Sandpaper

Automatic Traveling Head Beam Press For Sandpaper

Conveyor Beam Press; Die Cutting Press; Belt Beam Press; Conveyor Feeding Cutting Press

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

APPLICATION

This advanced machine features a liquid-filled double-cylinder press and four-column double-link auto-balancing system, ensuring ±0.2mm cutting depth accuracy. With Mitsubishi PLC control and servo motor drive, it offers precise feeding, high-speed cutting, and minimal wear. Safety enhancements include an isolation cover and robotic arm for stacking, combined with easy mold setting for convenient use.

TECHNICAL SPECIFICATION

| Model No. | ABC-R400 |

| Max cutting force(can be customized) | 40t |

| Press plate to table distance(can be customized) | 20-180mm |

| Effective worktable area(can be customized) | 400*400mm |